SLEWING RINGS TECHNICAL INFORMATION

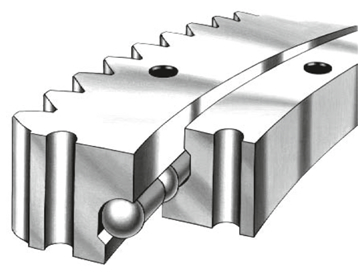

Vertical Thrust Slewing Ring

- * For application where the center of force remains within the slewing diameter under normal operating conditions

- * Thrust is transmitted at a 90° contact angle

- * Most efficient use of the slewing ring capacity

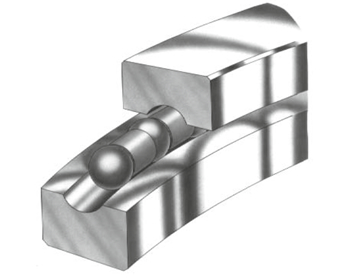

Vertical Thrust Slewing Ring

- * Without mounting holes and gears

- * Separate raceways, balls and spacers

- * Most economical solution

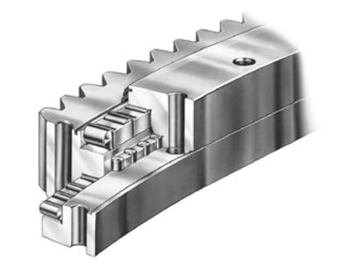

Three Row Roller Slewig Ring

- * Built with three independent rows ofrollers

- * Loads are transmitted directly to raceway surface, perpendicular to the load direction

- * So capacity of each rolling element and raceways surface is utilized in the most efficient way, providing maximum capacity for given size

- Low Frictional torque

Precision Slewing Rings

(single row ball, cross roller and three row roller configurations)

- * Runout tolerances to within .0003"

- * Concentricities to within .0003"

- * Parallelism to within .0003"

- * Bolt hole postions to .010" diameter

- * Gear precision equal to or exceeding AGMA 10

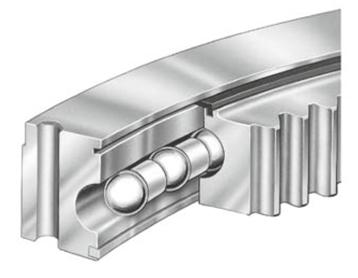

Roller/Ball Combination Slewing Ring

Application

- * Handle small eccentricities at relatively high axial loads